Equipment

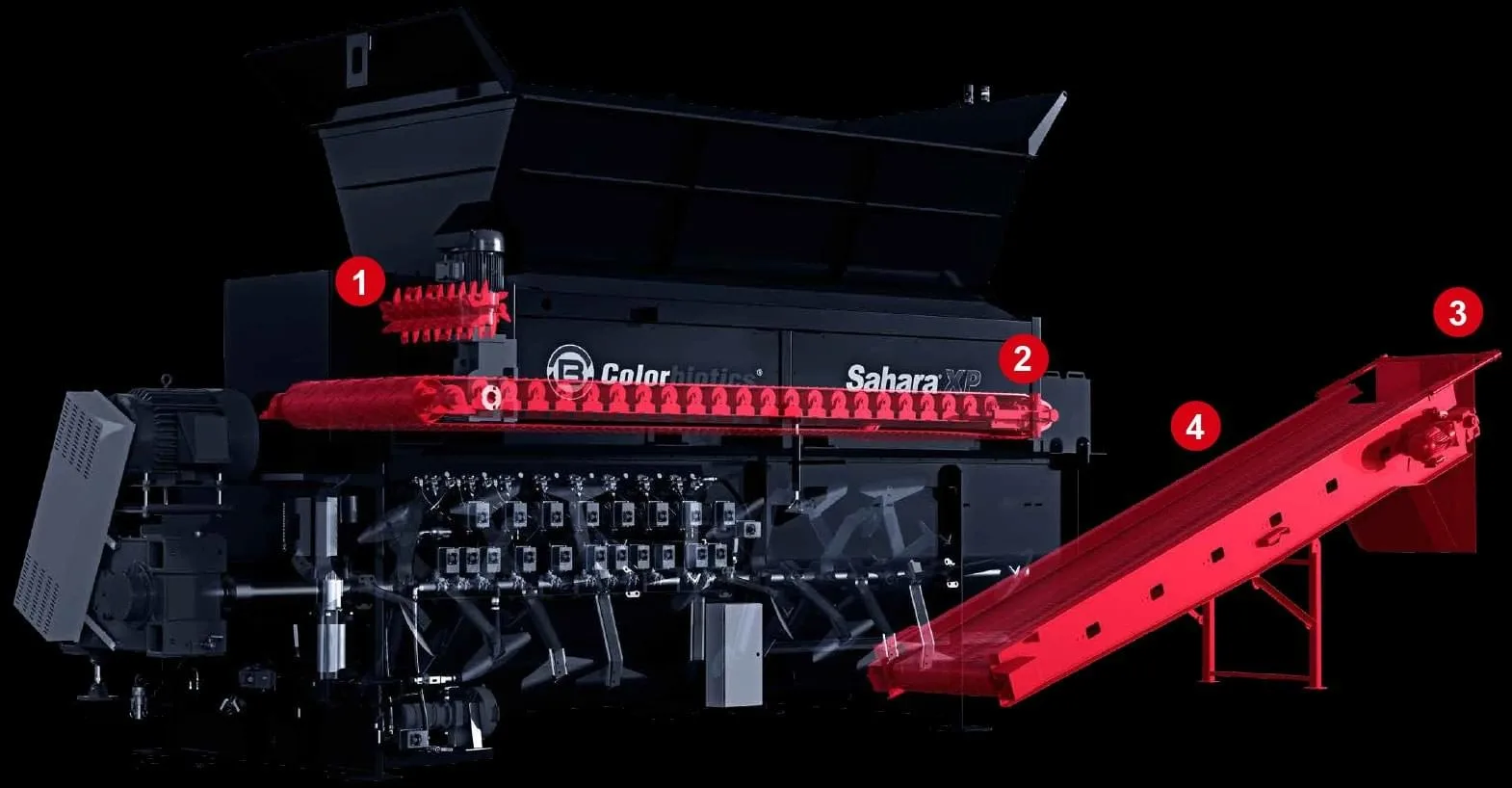

SAHARA® XP COLORING SYSTEM

No machine colors mulch like the Sahara XP. The architecture of the all-new, redesigned mixing chamber works with the innovations within to eliminate water waste and maximize color economy, trimming the fat from every last bucket of mulch.

Same time. Same place. Same color.

The XP’s belt feed hopper leaves nothing to chance: Each piece of mulch enters the mixing chamber at the same location and spends the same amount of time getting thrown around inside. That’s why your piles of product will all be the same color across hours, days, weeks or even seasons.

The difference in brilliance is size.

The XP’s on-demand atomizer nozzles use the water in your recipe to knife the colorant into a fine mist. That knifing action cuts down the colorant until its particles are small enough to cover the distinct surface characteristics of different wood fibers.

Each piece, every which way.

How do we pack so much muscle into such an efficient machine? The key is a patented process that we call bilateral agitation. With blades placed at mathematically precise angles, the XP increases retention time while also conserving energy.

SPECS

Technical Data

| Output: | 100 to 350 cubic yards per hour |

| Water: | 80 gallons of water per minute |

| Power: | 200 amps @ 460V 3PH |

| Motors: | Electric (up to 100 HP) |

Measurements

| Height: | 13 ft 10 1/16 in |

| Width: | 9 ft 6 in |

| Length: | 43 ft 3/8 in |

| Infeed: | 12 ft 3 7/8 in |

| Outfeed: | 6 ft 10 in |

Available Options

| Hopper size | |

| Motor horsepower | |

| Auxiliary pumps | |

| Cold weather package |

As simple as push to start.

If you can punch the numbers on a microwave, you can color mulch with GEM Studio. This do-it-all interface puts operators one tap away from the perfect recipe, right there on the side of the machine. Or via any device, anywhere.